Solder vs. Paste on the Core i9

Just recently we reviewed Intel's latest Core i9-9900K and Core i7-9700K processors. In summary, the 9900K was fast, but not fast enough to justify the price and that appears to be the general consensus amongst reviewers. Along with pricing, the other major issue was the operating temperature. Most reviewers are reporting very high stock temperatures using high-end coolers and this basically kills the overclocking potential.

In our review we spent quite a bit of time talking about the shocking thermal performance. We knew the 9900K was going to be a seriously power hungry CPU and therefore was going to be a hot item, I just didn't expect Intel's first soldered chip in a very long time to run quite as hot as it did.

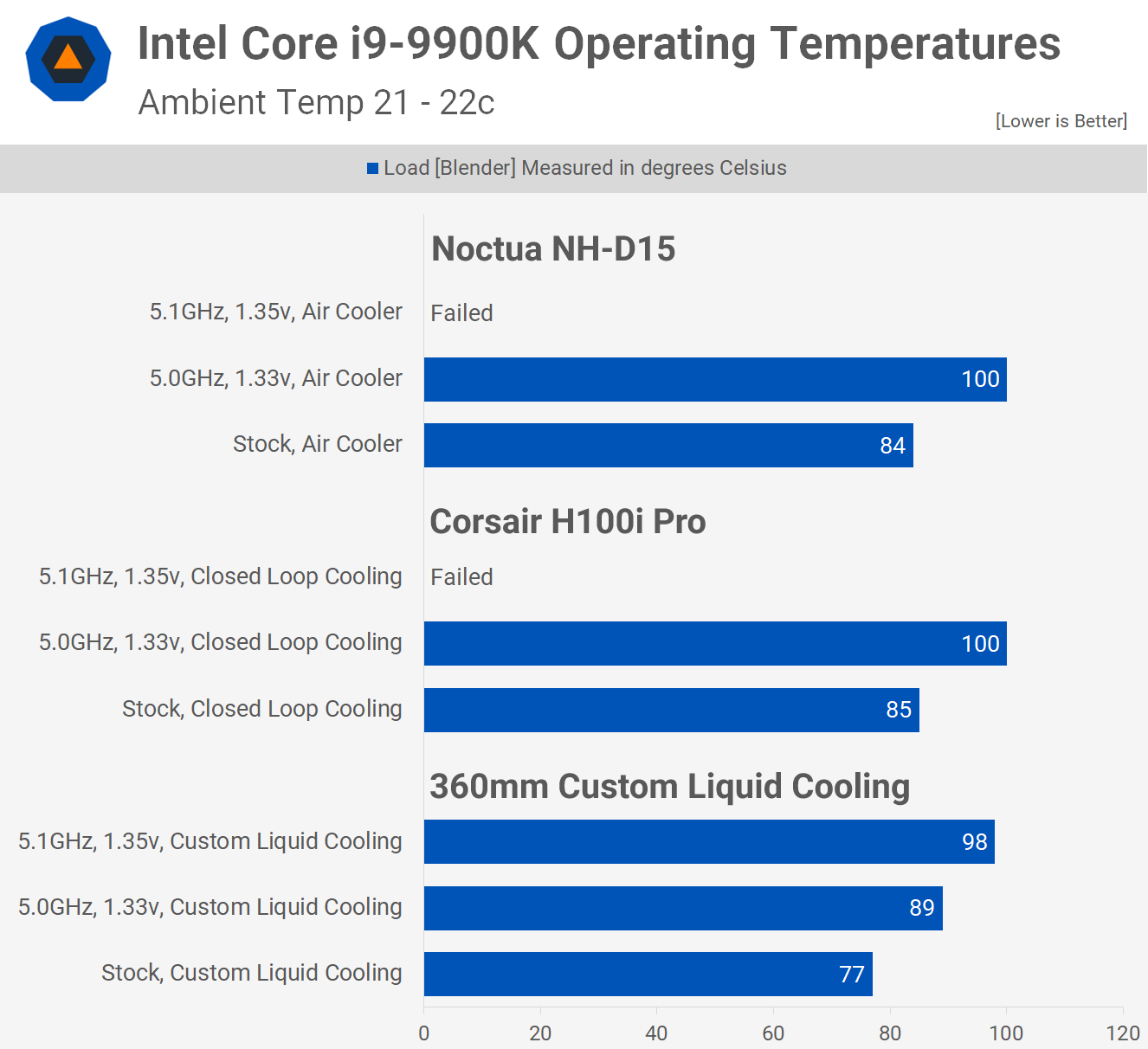

Using relatively low voltages at 5 GHz saw the 9900K peak at 100 degrees with the Corsair Hydro Series H100i Pro or Noctua NH-D15 and we're talking about some pretty premium coolers. This was worse than what we saw previously with the 8700K at 5.2 GHz, granted the 9900K packs more cores, but it's soldered whereas the 8700K uses Intel's notoriously rubbish thermal paste.

In the past we've delided 7700K and 8700K chips with amazing results. Using liquid metal dropped temps by at least 20 degrees though a big part of that improvement was achieved by removing the IHS glue which reduces the gap between the CPU die and heatspreader.

Still we know that soldering CPUs works a lot better than the paste method Intel's been using to save on production costs for years now. We know this because Intel's desktop CPUs ran much cooler back when they were soldered in 2011, the Sandy Bridge days for the mainstream desktop, while the high-end desktop parts were soldered up until the Broadwell-E era in 2016.

As an example, a Core i7-3770K running at 4.7 GHz using 1.35v would peak at just over 90 degrees running an AIDA64 stress test using a large tower style air cooler. Under almost the same conditions but with 1.4v, more voltage, the 2600K runs at least 20 degrees cooler.

That being the case we were expecting the 9900K to be something special, and not the kind of special it turned out to be. What we wanted to know is how much better is the solder method used by the 9900K than the paste of the 8700K/8086K? To find out we've disabled two 9900K cores which effectively turns it into an 8700K or 8086K. Admittedly, it's far from an exact science as the 9900K is a physically larger chip packing more L3 cache, but it's about as close as we can get with the hardware we have available.

The Core i5-9600K might make for a better comparison but we're still waiting for our chip to arrive, so we can revisit that down the track. The 9600K is just a 9900K with 2 dies disabled, but you do get the smaller L3 cache. Anyway, this comparison should give us a pretty good idea of just how much of an improvement Intel's STIM makes.

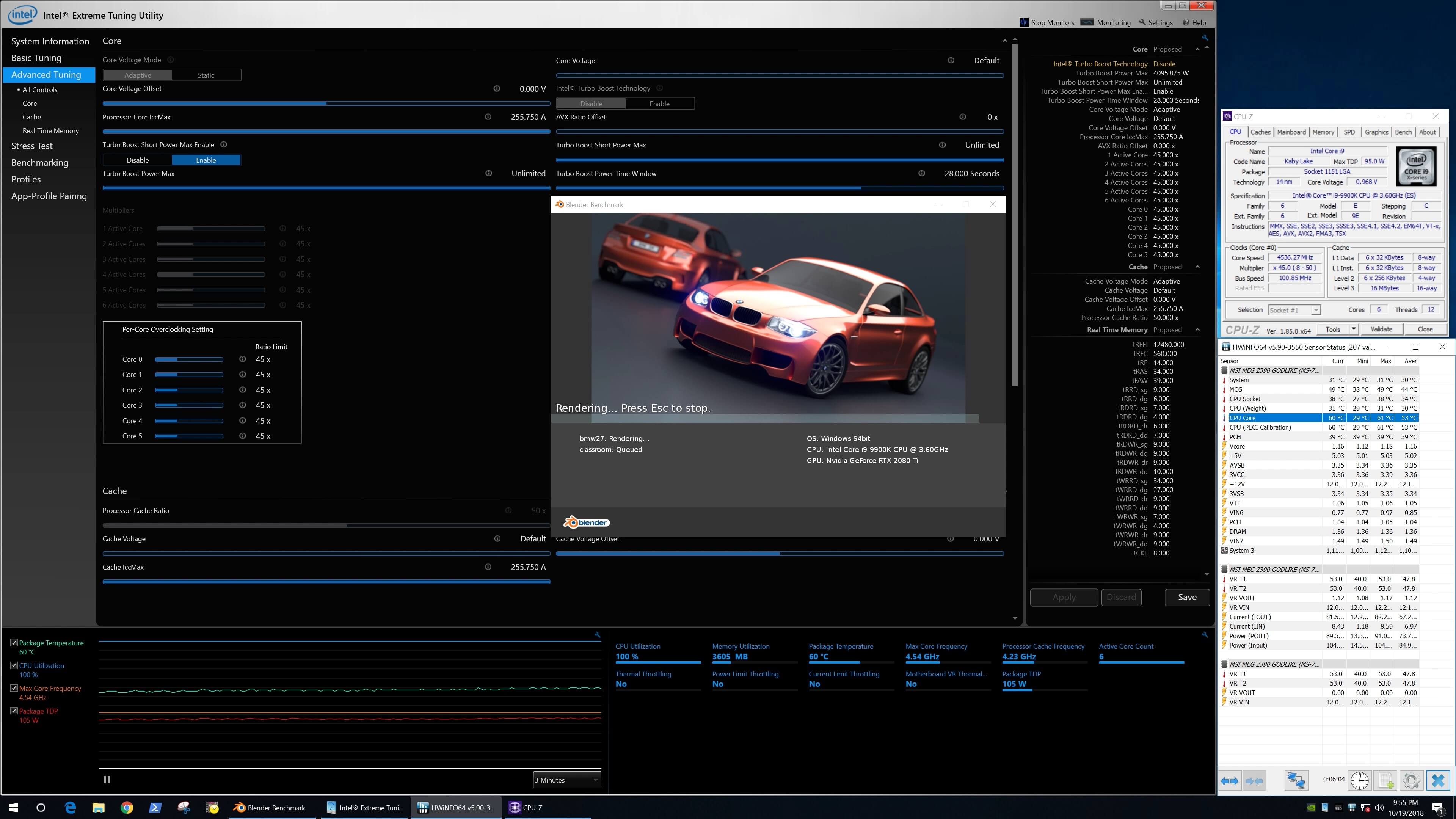

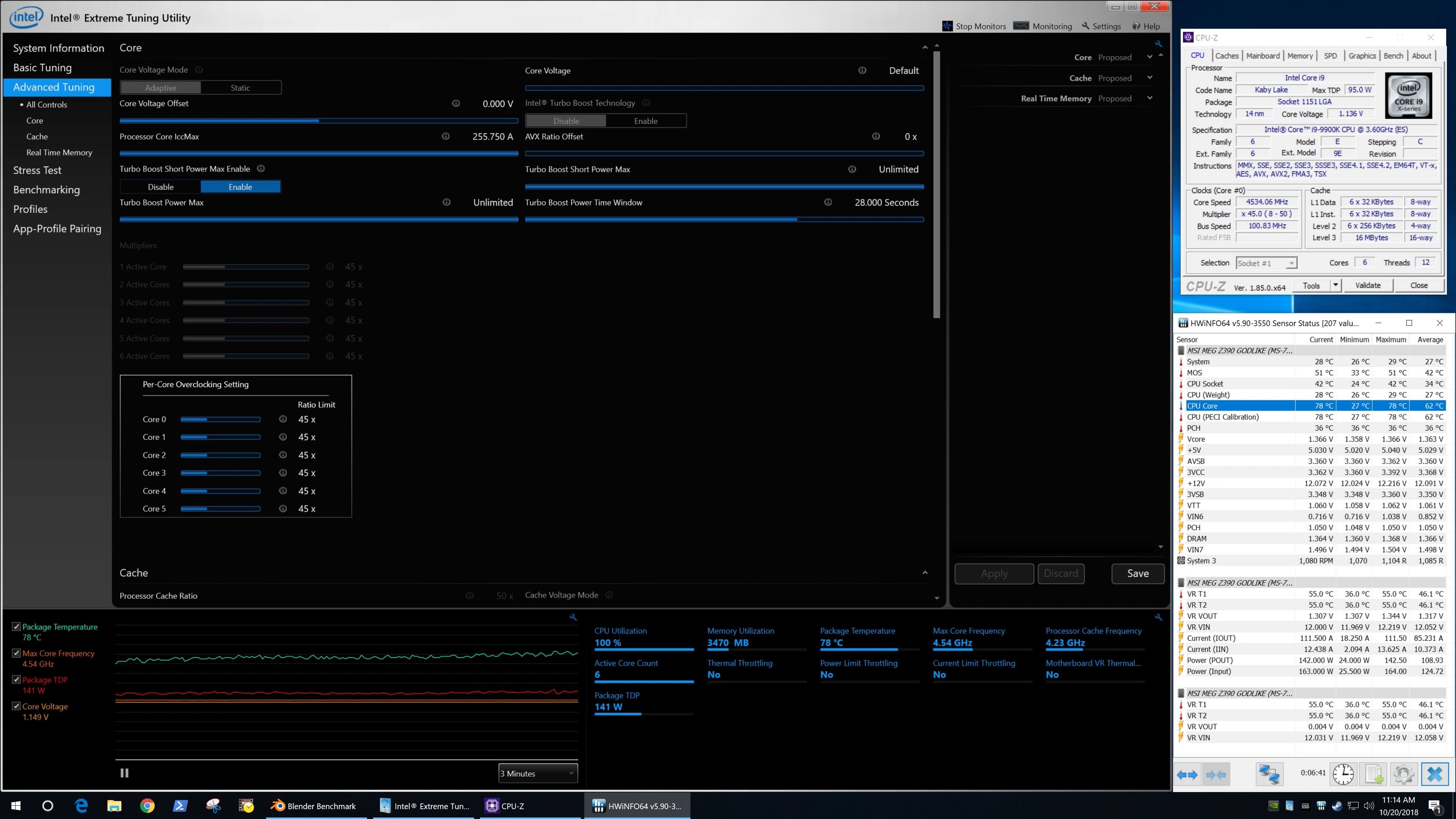

For the first test configuration we locked both the 9900K and 8086K at 4.5 GHz on the MSI Z390 Godlike. Blender was used to place full load on all cores and again both CPUs were tested with 6-cores active and for this test the voltage options were left on auto.

This saw the 9900K running at 1.16v for the most part and the 8086K at 1.26v. The 9900K saw a peak core temperature of 61C and the XTU software also reported a 61 C package temperature.

The 8086K on the other hand went as high as 74 C on the package with a peak core temperature of 72c. So for the 4.5 GHz auto voltage comparison the soldered method reduced temperatures by 11 degrees, a 15% reduction though as I noted voltages were also 8% lower. The package TDP was also 16% higher on the 8086K hitting 125 watts opposed to just 107 watts for the 9900K.

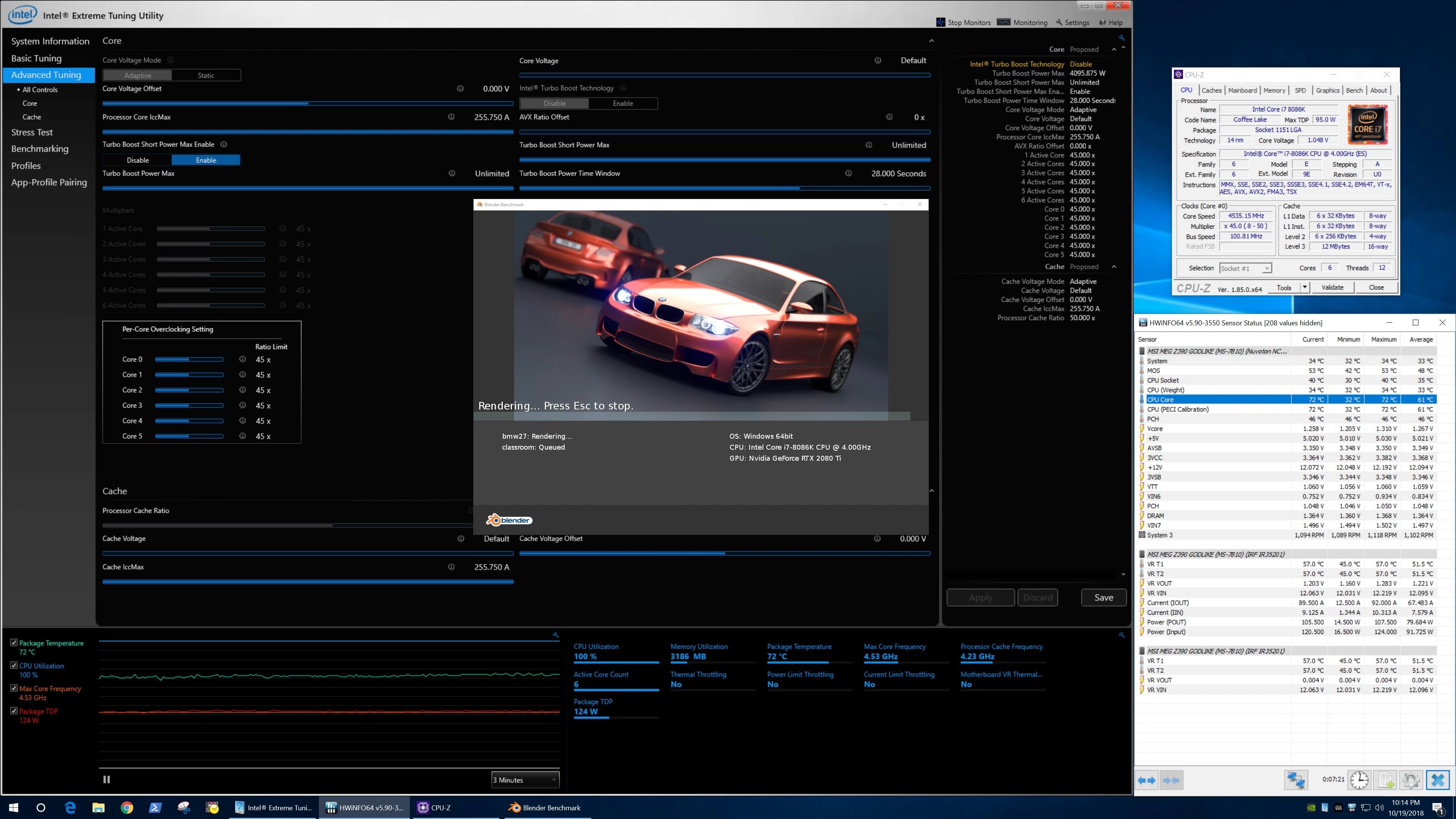

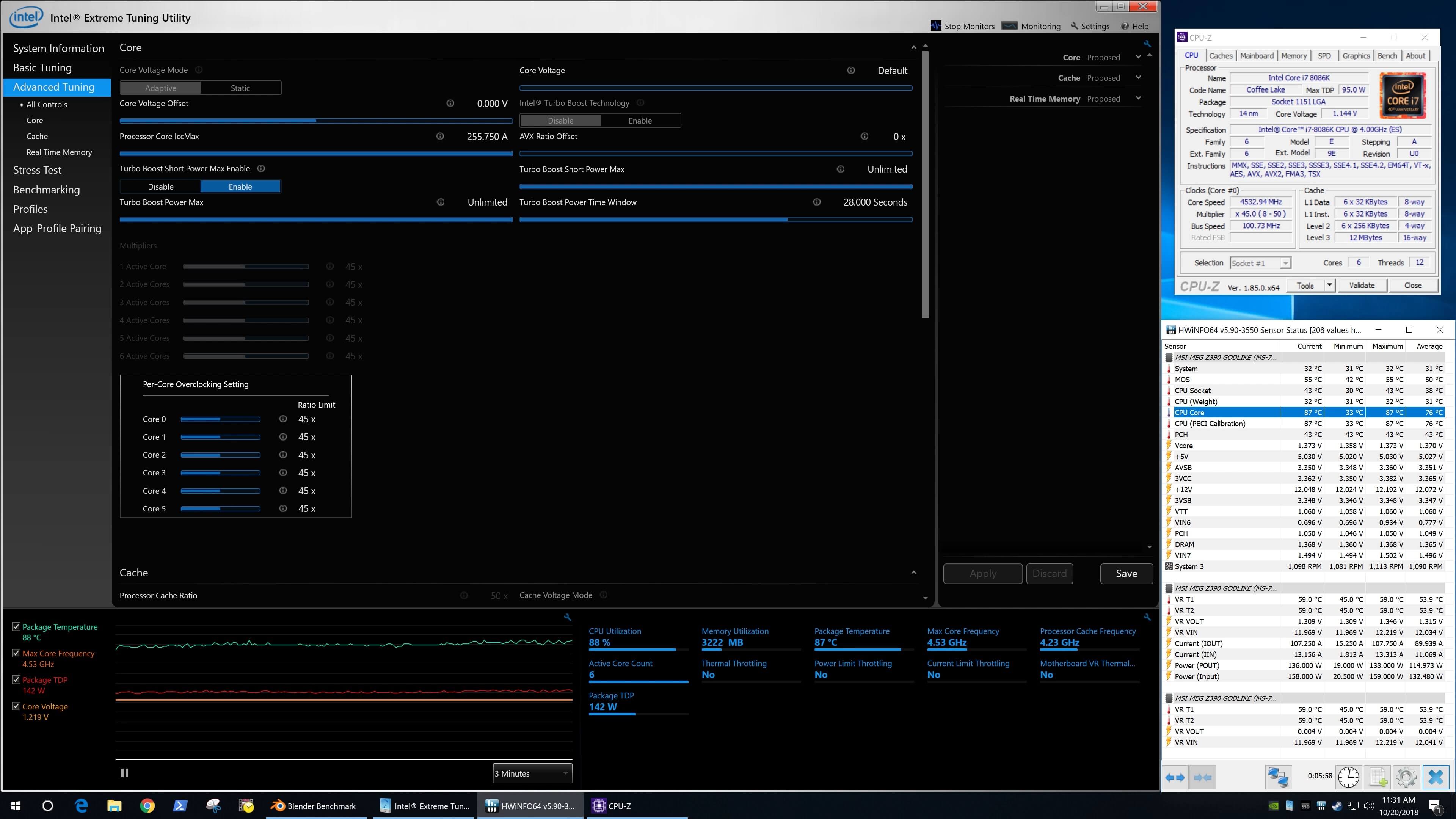

That being the case for the next test I locked the voltage at 1.35v on both CPUs, leaving the operating frequency at 4.5 GHz. This evened things up and now the 8th gen processor was hitting at package TDP of 145 watts while the 9th gen chip hit 144 watts. That's a 16% increase for the 8086K from the previous test and a 35% increase for the 9900K.

This saw the 8086K hit a peak package temp of 88 C and a core temp of 87 C with a typical load voltage of 1.373v.

The 9900K on the other hand peaked at 79 C for the package and 78 C on the cores while running at 1.366v. So that's a 9 C improvement for the 9900K, allowing it to run 10% cooler.

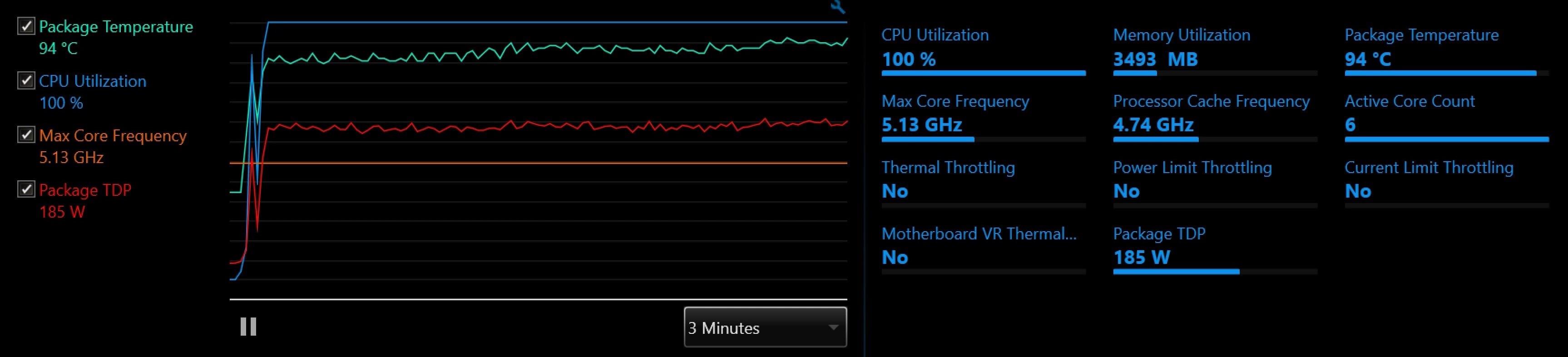

That's a decent result for the soldered 9900K, that said we're already almost at 80 degrees, so how much hotter do things get at 5.1 GHz with the same 1.35v and what are the improvements over the 6-core 8th gen part? If you recall I opted to run my 8700K test rig at 5 GHz as the temperatures were much more acceptable than what I was seeing at 5.1 GHz and the same is true for the soldered 9900K.

Here we see the 8086K hitting a peak temperature of 94 C for the core and package at 1.380v, this resulted in a package TDP of 188 watts. So pretty toasty stuff and again this is why we decided to run these processors at 5 GHz for GPU testing.

In comparison the 9900K peaked at 91 degrees for the core and 90 C for the package. The average voltage during the load test was 1.366v and this resulted in a package TDP of 181 watts. So this means when overclocking the soldered chip was just 3 degrees cooler than what we saw with the 8th gen model using paste. This also explains why we saw a 98 degree operating temperature with all 8-core active, that's actually a much smaller increase than we would have guessed.

So why does the 9900K go from offering a 9 degree improvement over 8086K at 4.5 GHz to just 3 degrees cooler at 5.1 GHz? My guess would be that we're reaching a thermal bottleneck with the 9900K. Der8auer recently discovered when delidding the 9900K that the die is significantly thicker than that of the 8700K, I won't give his exact measurements, if you want those please go check out his video, he's done some great work there.

As Der8auer notes the thermal conductivity of the silicon isn't great, so the more of it you have the more thermal resistance you'll face and this appears to be an issue for the 9900K. It's my assumption that this isn't as much of an issue at 4.5 GHz but as we increase the thermal output the silicon bottleneck becomes an issue and starts to degrade thermal performance to the point where soldering the IHS is of little benefit. To prove this Der8auer sanded down the Core i5-9600K silicon by 0.2mm and this reduced the temperature by 5.5 C, a rather significant improvement.

On a slightly different subject, readers were asking how is it possible for the Ryzen 7 2700X, also an 8-core/16-thread CPU, to run so much cooler? The main reason is clock speed, the 9900K with just 6 cores active went from 78 C at 4.7 GHz to 91 C at 5.1 GHz, a 17% increase in operating temperature. The 2700X can only be overclocked to around 4.2 GHz and by default runs all cores at 3.8 GHz.

Also helping with thermals is the CCX design which sees them lumped into groups of 4, rather than a solid block of 8. Basically Intel has been too aggressive with clock speeds and this has resulted in an 8-core CPU that's almost too hot to handle.

There's likely a number of reasons why Intel had to increase the height of the silicon. I doubt this to be incompetence, but it could well be a cost saving thing. As I understand it, soldering the 8700K would be risky as the silicon could crack during the heating of the soldering process. Intel has been forced to increase the thickness of the silicon to better handle the stresses of the heating process required to melt the solder. Thinner silicon would complicate the process, likely making it more time consuming and therefore more costly.

Then there is the thickness of the solder, which some would say is way too thick. Again, this could be true but Intel also faces damage here, thinner solder will be more prone to cracking, particularly after prolonged use. These chips heat up fast and depending on the cooler used can cool down quite rapidly and this places a lot of stress on the solder layer.

Now you can delid the 9900K as Intel didn't want to go with a super hard solder, again to try and avoid cracking. There's certainly more work involved to clean it up as the solder is much harder to remove than paste, but it can be done. Reapplying with liquid metal will reduce temperatures by a further 5-10 degrees, so there is that. However we're not fans of delidding, it voids your warranty, it can be risky and we'd rather you didn't have to do it, particularly when spending at least $500 on an unlocked CPU that's intended to be overclocked.

It's a fun and challenging experiment for mad enthusiasts with deep pockets, but for those who just want to overclock without getting the lab coat out, the crazy high 9900K temps will be frustrating. At the end of the day it seems Intel is pushing everything to the limits and therefore were forced to solder in order to maximise thermal conductivity. The gains are reasonable at stock frequencies, they just aren't as impressive as we'd hoped for. Overall it's still a better method as we are seeing improved thermal performance, unfortunately though we are only talking about 3-4 degrees, 5 at the most when overclocking.

Shopping Shortcuts

- Intel Core i9-9900K on Amazon, Newegg

- Intel Core i7-9700K on Amazon, Newegg

- Intel Core i5-8400 on Amazon, Newegg

- AMD Ryzen 5 2600 on Amazon, Newegg

- AMD Ryzen 7 2700X on Amazon, Newegg

- AMD X470 motherboards on Amazon